I had the opportunity to visit with Mel Smith and look at some very interesting weapons from his collection. Today’s write up is about one of the most interesting ones. This is a Steyr bolt action sheet metal stamped prototype rifle. This rifle was made as a contender to replace the 98 mauser. It was made to be produced with less expensive sheet metal stamping instead of the usual forged and machine method of making a rifle.

Studding this rifle I can tell you that the stamping dies and equipment would have been extensive. It is truly a work of art. I hope you enjoy the photo essay.

This is the Steyr G42 (St)

Starting with the rifle.

The sheet metal in that receiver is thick. The tonnage for that pressing would be quite large.

The sheet metal in that receiver is thick. The tonnage for that pressing would be quite large.

The sear assembly.

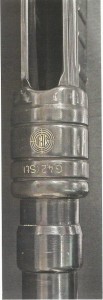

The bolt group.

I like the design of the bolt and the removable bolt handle.

I like the design of the bolt and the removable bolt handle.

The magazine and follower. What a set of stampings.

Trigger and Trigger guard.

Stock and hand guard.

The rear sight. Even this stamping is interesting.

Again I would like to thank Mel Smith for allowing me to look at this rare and unusual rifle.

Thanks for that interesting rifle, it is hard to believe that they were pursuing a bolt action rifle at a time when the MP44 sheet metal rifle was going into production. The Steyr rifle is a beautiful piece of machinery but would not have made any sense as a combat weapon. Harry

Cool!!!

Are locking recesses machined into the barrel (or barrel extension) or there is a front trunnion there?

There is a front trunnion that is swagged in the sheet metal receiver.

Got it, thank you.

Another unusual thing is that channels (4 of them) in the rear portion of the receiver … I wonder what they are for?

My best guess is they add structural strength to the stamping … but maybe they guide the bolt or give room for dust and mud not to jam the action (considering that it is a military rifle)??? Any ideas?

Your right Hrachya H, It is cool! The barrel to receiver transition caught my attention too…

Chuck, What did they use between the barrel steel and the stamped receiver?

If they had ever got all their ducks in a row they could have stamped those out much faster than milling all the K98k parts like they were doing in 42. I agree time and money would have been better spent manufacturing MP44s. But they learned a lot I am sure from this project that would have been later applied to the production of the MP44. Bill

Chuck – Would this Steyr rifle be less expensive or faster to manufacture than the Kar.98k, given the manufacturing technology of the day? Looks to have a greater parts count and a number of tricky welding operations.

Given time and tooling I think it would have cost less and been fasted. However with that said I think they would have been better of spending there money and time on an improved semi/full auto rifle.

low cost sheet metal gewehr….. the mix of a k98 and a citroën 2cv

i think I can do most simple.

what is the thickness of the receiver steel sheet? 2,2 mm ?

[…] Here is a cool article on a prototype Steyr stamped replacement for the Kar98k http://gunlab.net/steyr-sheet-metal-rifle/ […]