Now that I am back into the shop it is time to get back to projects that was started years ago. The first project on the list was the Sudanese lower receiver. It had been drawn up in a solid model years back when the modeling program that was used in the shop was Solis Works, however due to the cost I shifted modeling programs and we now use Fusion 360. The model was moved from solid works to fusion 360 but you do not get any of the steps or even a drawing. All you transfer is the solid model. Some changes can be made to the solid model but it is not an easy task.

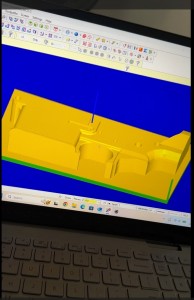

The first step was to write a cam program. With a friends help this was accomplished.

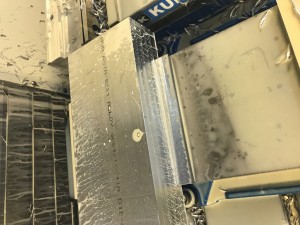

With the program written it was time to set up the HAAS machining center. All the tools were loaded and touched off and the program loaded.the first op was ready to go.

This is a test run and this receiver will be destroyed due to the material is the wrong material. The actual receiver will be made out of 7075 aluminum and the test piece is being made from 6061 aluminum. 6061 is about 1/3 the cost of 7075.

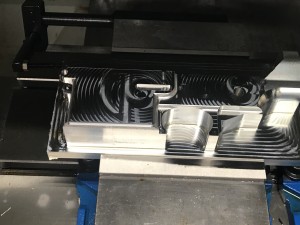

This photo shows the completion of op1. To deal with all the surfaces on the receiver there was a lot of fine detailed machining, generally referred to as surfacing, here are a few pictures that shows some of the finer details.

This photo shows the completion of op1. To deal with all the surfaces on the receiver there was a lot of fine detailed machining, generally referred to as surfacing, here are a few pictures that shows some of the finer details.

The radius on the front of the receiver magazine housing.

The radius on the front of the receiver magazine housing.

The detail around the magazine release.

The detail around the magazine release.

The next post will be about op 2

The next post will be about op 2

Leave a Reply