Looking for G-43 fire control parts. Hammer,trigger,sear. This is for one of the projects we are working on. A friend of Gun Lab has helped out with this. Thanks

|

We are now taking reservations for out reproduction VG1-5 rifles! Price is $4000, and they will be ready to ship once ATF gives final approval on the design. The get on the priority list, contact Matt or Greg at Allegheny Arsenal – (814) 362-2642. No payment will be taken until the guns are ready to ship. With the new Bambu P2S printer here I decided to start printing out some of the components of the 1917 trench carbine to verify the design and measurements. The first part that I printed out and checked is the fire control group. After it was printed out it was checked with actual components to verify proper fit up.

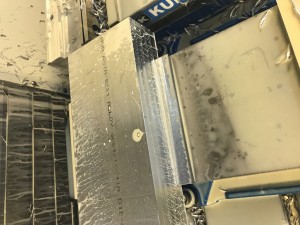

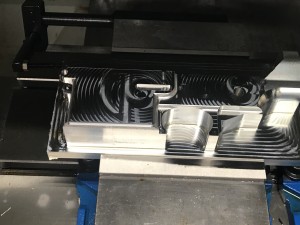

A number of changes were made to the Sudanese AR-10 lower receiver. Selector stops were added and a new profiling program was used to allow for a better finish around a few areas of the receiver. Then a second lower was machined out of 6061 to verify the changes. During the process of machining a few issues were notes. The first is that with the new tool path it left on a thin section of metal. The magazine release button also changed from an inside cut to and outside cut.

In this post I am going to chat about a single part. The Lock frame stop. This individual part is common only to the carbine. The take down lever. you can see it here in this photo that I found on line.

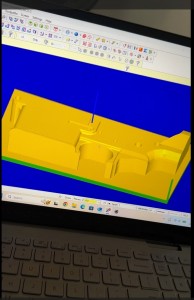

This is the solid model.

I have received a number of questions concerning the Japex wire EDM that I have. Where can you get help repairing the machine, where can you get consumables for it and is there anyone that can help with getting it operational. Hope this helps all the people looking for help with there Japex machines. This Project is definitely interesting one. By using a combination of engineered drawings, pictures and C96 parts to measure I have been able to get a reasonable set of solid models. I started on the lower receiver but it did not take long before I realized the the fire control group holds the key to some of the interior dimensions, information needed to allow me to draw up the lower and match it with the upper slide assembly. These are the pictures of the different fire control groups.

With op 1 completed it is now time to work on op 2 and 3. First a fixture needed to be machined to hold the machined receiver to all finishing the other side.

I happen to like the Mauser broom handle pistol. I know it is not well balanced or comfortable to shoot, but it is an iconic and historical weapon. I have a small collection and I am always looking to add to it.

It is a classic design

I have also located patent drawings that has helped with some concepts and line drawings. There is also a c-96 cut away in my collection which allows be to study the concept and method of operation

When the rest of the fire control are completed then an assembly will be made showing all the parts as a completed model. I will then perform an analysis to check proper fit and alignment. Once I am at this point of the design I will make a 3D print of everything and actual do a physical inspection. This is a Schnellfeuer frame I did a while back.

Now that I am back into the shop it is time to get back to projects that was started years ago. The first project on the list was the Sudanese lower receiver. It had been drawn up in a solid model years back when the modeling program that was used in the shop was Solis Works, however due to the cost I shifted modeling programs and we now use Fusion 360. The model was moved from solid works to fusion 360 but you do not get any of the steps or even a drawing. All you transfer is the solid model. Some changes can be made to the solid model but it is not an easy task. The first step was to write a cam program. With a friends help this was accomplished. With the program written it was time to set up the HAAS machining center. All the tools were loaded and touched off and the program loaded.the first op was ready to go. This is a test run and this receiver will be destroyed due to the material is the wrong material. The actual receiver will be made out of 7075 aluminum and the test piece is being made from 6061 aluminum. 6061 is about 1/3 the cost of 7075.

It is hard to believe that I have been shut down or at least stop posting for over 5 years. Life just got in the way and something needed to be set aside. I will start with what is new here. I finally retired, sort of, I still work for the company that bought me out. However, I work a lot less hours and not have time for the shop and making things. The first thing I did was to start repairing broken equipment and actually get the shops back in some kind of order, still have more to do in that respect and I don’t think that will ever stop. The major projects that I am currently working on is first and foremost getting up to speed learning the new solid modeling program that we currently use. In the past I used Solid Works but the cost got to be prohibitive and I have shifted to Fusion 360. I started in earnest about 3 months ago. To allow me to learn Fusion 360 I bought a number of books with engineered drawings and finished every drawing at the same time I checked out ever Fusion site that I found and followed them along on how they did certain tasks then I watched the game show on youtube dealing with a contests between individuals using there preferred solid modeling program. After about 2 months and 800 drawings completed I started working on drawings that I had to make them into solid models. I have to admit that actual engineered drawings are a lot harder then anything in the books or on youtube. However, I was able to start working my way through the drawings then it was onto reverse engineering parts using what ever information I could find and pictures to trace over. this leads me to where I am at now. A number of the projects that was worked on previously had to be re-modeled. I started with the AR-10 Sudanese lower receiver. With the drawing complete I was able to program the solid model for manufacture, I did have some help with this. The next post will be about making the lower receiver, spoil alert it turn out perfect for the first 4 ops still a couple of ops to complete. My plan is to make 10 receivers and then go on to the next project. I still need to finish the drawings on the Portuguese receiver but I will finish this project before I remove all the tooling and start on something new. I have no desire to make any more receivers then a limited supply as I have other things I want to do. It is good to be back in the shop and having fun. There are still a number of projects around the property that need my attention and money so unfortunately not all my time will be in the shop.

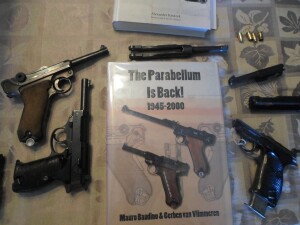

The myth of east-german newly manufactured P.38 pistols PART II

Thanks for all the comments on our P.38 post! Initially we wanted to make a video covering all the questions raised but rather doing another post. First we will talk about the technical aspects and then the historical context. So why new barrels? The old ones were often in poor condition due to corrosive ammo (primers) and steel jacketed bullets. What holds the sleeved barrel in place? Most likely interference fit but could also be braced even though no traces visible. The post war P.38/P1 pistols have a fully sleeved barrel. At the first variant the barrel liner was held in place only by a cross pin. That prooved to be unsatisfactory because the barrel liner started to walk out towards the muzzle under intense use. The second variant features a collar all around (first a smaller, later a wider one) giving the barrel liner sufficient support. A croatian P.38 inspired gun (PHP) features a barrel sleeved into the barrel block secured with a cross pin. Wasn’t manufactured for long and didn’t see much use. Years ago at the IWA trade show I’ve seen chinese copies of the SIG P226/P228 with the barrels clearly sleeved in the square block which is forming the locking/unlocking cam and locking shoulder. PIC 1a So with a barrel only press fitted to the barrel block they probably would have experienced issues sooner or later. The barrel on the pictured gun looks brand-new. Wouldn’t shoot any of those much. First N-series gun being N1000 – correct! The book we referred to in part one actually lists this number among the guns that are confirmed to exist also including N1120. Which would actually mean that 121 N-series guns were made… PIC 1b book cover When looking at the fired Vopo P.38 cartridge casings those markings looked somehow familiar. Took me a while. Well, haven’t fired a Luger P08 in years! PIC 2 To the left two shells from the Vopo P.38 – on the right two shells from a 1939 Mauser P08. So looking down the barrel of two Luger pistols (1939 Mauser right, 1916 DWM left) they have a step in exactly the same spot as the Vopo P.38 barrel in the middle. PIC 3a At the 9mm Luger pistol that step/sealing rim was employed to achieve a better gas seal. They apparently didn’t trust the almost straight-walled 9×19 casing compared to the bottlenecked .30 Luger. Didn’t worked very well on the Luger tested here since the cartridge casings look a lil bit fouled past the sealing rim. The P.38 though never had that stepped chamber. According to the book “The Mauser Parabellum 1930-1946″ that sealing rim was dropped at the Luger pistol sometime 1941/1942 since it caused extraction issues with steel cased ammo. PIC 3b book cover So did they actually made complete new P.38 barrels in East Germany or conveniently covered the sleeving by arranging the ring joint being in the same spot as the sealing rim at the Luger pistol? Or if they made complete new barrels why employing that unnecessary sealing rim at the P.38? Not enough tooling so they used the same chamber reamer they used for the newly made Luger barrels? BTW, do east German Luger barrels have that sealing rim? No Vopo Luger was available to check. And why would they have reintroduced that sealing rim anyway since East Germany used steel cased ammo as well? Speculation at this point. To me it still looks like a sleeved barrel. Esp. those peening marks where the barrel sticks out of the barrel block. Only the new Vopo P.38 barrels have these markings and I can’t even figure out what machining operation would have left these marks and for what reason other than covering a ring joint. The only way to find out indeed seems to be cutting on of those Vopo barrels. Maybe there is a cutaway model out there that could help to clarify the matter. Was also looking for deactivated barrels as they are common in Europe with the barrel slotted or otherwise cut open. No luck so far…

Now lets go to the historical aspects… In 1945 the Walther factory was first inspected by American troops and their technical intelligence teams: https://forums.g503.com/viewtopic.php?t=250311 PIC 4 “The P.38 Pistol” states on page 55 – when on April 4, 1945 American troops arrived at the Walther plant 1,600 P.38/HP were found ready to ship and others still unfinished were assembled and taken as war souvenirs. So after the Americans took everything they were interested in plus everything else they didn’t wanna leave for the Russians, the second raid happened when the Russians arrived on July 3rd 1945. And the Russians took everything! Two aspects played a role. First they wanted to strip the former enemy of all resources that would make Germany a powerful and dangerous player ever again. And they were still traumatized by the experience not having enough guns when WW2 started. In Stalingrad they only had one rifle for every other soldier. The unarmed ones were supposed to pick up a rifle from a fallen one with a rifle! The second aspect is that Russia was lacking almost everything regarding modern equipment (by standards back then). My grandma told me when a group of Russian soldiers was looting the house right after the war one of them was putting his boot in the toilet trying to figure out what that appliance was good for! He simply didn’t know what it was. Now before the thousands of Russian readers we have will all get butthurt – they had a very few big and some smaller cities in Russia but 95% of the country was just outback. With these primitive farmer’s cottages, unpaved roads, a well in the backyard and a hole in the ground to take a dump! So they took EVERYTHING they didn’t have back home in Russia. Nothing remotely usable was left! According to documents of the Soviet Main Directorate “Beutegut” (war booty) 60,149 pianos, grand pianos and accordions, 941,605 pieces of furniture, over 3 million pairs of shoes and 1,2 million winter coats, clothing, bed linen and furs were removed from the Soviet occupation zone (SBZ). And in 1946 the buildings of the Walther factory were demolished. That’s why the Walther factory never became a part of the ETW conglomerate (VEB Ernst Thälmann-Werke, founded 1954). Same story happened with the Mauser factory in french occupied Germany. There is a very interesting book telling a lot about these post-war aspects: PIC 5 book cover Before the demolition of the Mauser factory was ordered in November 1947 several trains with guns, parts, equipment, machinery etc. were leaving for France. The question that there was enough experienced personal available. In that book German engineers questioned in 1945 stated that they were already lacking trained staff after 1942! And it would take an estimated two years to get production and R&D to the level before 1945. And in the soviet zone no one was employed in essential functions who was formerly engaged in the NSDAP. In contrast to the western Allies who used former cops etc. after a short de-nazification period. That was reducing the available qualified workforce in East Germany even more. And we are talking about the late 40’s and early 50’s when these “new” P.38’s were made. According to the aforementioned book East Germany received a large number of WW2 guns from the Russians in 1953. The better ones were reworked the others used for spare parts. Coincidentally all the N-series barrels both P.38 and P08 are dated 1953, most 9/53? And when the mass production of the P.38 was already planned why having a production line for the way more complex P08 set up as well? Regarding the limited resources at that time it wouldn’t make any sense. So could all these “newly made” P.38’s and P08’s be reworked WW2 guns? Absolutely. Same goes for the Walther PP post-war production. All of those “1001” guns could be reworked WW2 guns. Here you can see serial No. 132270. http://www.hermann-historica-archiv.de/auktion/hhm50.pl?db=S-50.txt&f=ZAEHLER&c=1153&t=temartic_S_GB&co=1 They for sure didn’t make over 130,000 of these! That’s a rework retaining the original number. The expert literature often gives conflicting info as well and should be taken with a grain of salt. “The Parabellum is back” on page 90 shows a list of guns manufactured at Mauser under French control stating that 35,000 P.38 pistols were made until March 1946 and 20,000 Mauser HSc pistols. Manufacturing ended in May 1946. On the same page a production overview including April 1946 lists only 13,971 HSc pistols! The book “The Mauser Parabellum 1930-1946″ shows the very same list for the complete time frame till May 1946 but only 3,500 P.38! Which clearly looks like a transcription error. Both books published 2010. The book “The P.38 pistol” (2017) gives on page 176 a total of 37,855 P.38’s made under french control. Which could very well be since the chart in “The Parabellum is back” on page 90 lists 36,720 P.38 made including April 1946 plus likely a few more made in May before production ceased. I’m aware there is the wish of every collector to possess something special, only made in very limited numbers, but except for a few special markings not even consistently used, I haven’t seen any physical evidence proving actually newly made (not assembled) P08/P.38/PP at that time. Things were changing quickly though in the mid-50’s with establishing the West German Bundeswehr in 1955 and the East German NVA in 1956 … If any of our readers has more information or other aspects we should cover – please let us know. |

||

|

Copyright © 2026 GunLab (KnownHost) - All Rights Reserved Powered by WordPress & Atahualpa |

||